GROUNDING SOLUTION

Increases safety at the loading rack with positive results.

Garnet’s PosiGround™ Truck Grounding Control System helps prevent fires and explosions caused by a static discharge that builds up during the transfer of flammable liquids.

Contact us and let us help you upgrade your safety standards with the SeeLeveL PosiGround™.

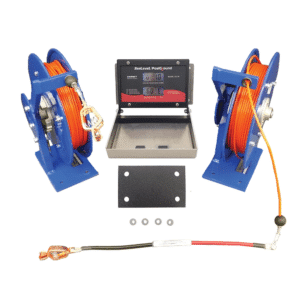

Truck Grounding Controller

Model 672-H

The SeeLeveL PosiGround™ Truck Grounding Control System helps to prevent fires and explosions produced by a static discharge that builds up during the transfer of flammable liquids. Monitors the ground status and can be configured for either 250-ohm high resistance range or a 10-ohm low resistance range; activates alarms if the ground connection is lost during the transfer.

- Verifies that the truck is grounded

- Powered from 12V truck power

- High (250 ohms) or low (10 ohms) resistance range

- Displays the actual ohms level of resistance

- Serial port connector for RS-232 communications with a computer or PLC

- Built-in diagnostics

- Warning horn and final alarm

The PosiGround ™ system operates by connecting one clamp to a metal object which looks like it should be grounded, and connecting the other clamp to another metal object at least 20 feet away which also looks like it should be grounded. Ideally, both objects should have a buried portion. Check the display, it should show “GO d”, indicating that the ground is “Good” but that PTO has not been engaged. The actual ground resistance in ohms can be recorded from the top display if desired. Loading or unloading by engaging the PTO can now be started. If loading is attempted before the ground connection is made, the warning horn will sound for a set time, and then the final alarm will activate. Alarm condition remains until the ground connection is made. If the ground connection is lost during loading, the warning horn will sound for a set time, and the final alarm will activate. When loading is complete, shut down the loading system and then disconnect the grounds.