FLAMMABLE LIQUIDS SOLUTION

Equipping you with measurement for tanks hauling hazardous liquids.

The SeeLeveL Special™ system is designed for tank trucks hauling flammable liquids, offering precise digital readouts of the fluid levels inside the transport tank. Its all-digital design eliminates reading drift, ensuring long-term accuracy under all conditions without the need for costly and time-consuming recalibration. The intrinsically safe fiber optic connection makes it suitable for both hazardous and non-hazardous applications.

A variety of configurable components have been developed for transport applications, including tank level gauges, spill prevention systems, loading rack controllers, grounding control solutions, and related accessories. These work together to provide solutions for your liquid management needs.

Let us assist you in finding the right system that meets your operational goals.

Core System

Start with a precise level and volume gauge system.

Level and Volume System

Model 808-P2

The SeeLeveL Special™ 808-P2 is a versatile digital continuous level measurement system, now featuring enhanced capabilities. The upgraded design includes new functions such as temperature and battery condition display for the new 810-TX sender bar, an integrated driver module for the SeeLeveL MultiRack™, and short-circuit protection on alarm outputs.

The system interfaces with both the 810-X and 810-TX sender bars, offering broad applicability in fluid level monitoring—particularly in crude oil transport and other contexts involving flammable liquids. Additional systems can be integrated with the SeeLeveL Special™ to further enhance functionality and meet operational requirements.

See additional support products below.

- Resettable horn alarm

- SpillStop™ output

- MultiRack™ Controller output

- Communications output

- Intrinsically safe

- Weather resistant enclosure

- Internally powered

- Works well in a variety of liquids

- Stainless steel float option

The 808-P2 operates using a magnetic reed switch sender bar detecting the float magnetic field. The system provides a stable resolution of 8 mm (1/3”) and the fixed position of the reeds eliminates any need for recalibration during the life of the gauge.

- (1) 808P2 Display

- (1) Brass Optic Fitting

- Programming Available Upon Request

- (1) 810X Sender Bar with (1) Brass Optic Fitting

- (1) Brass Optic Fitting

- (1) Carbon Steel Compression Fitting

- (1) Stainless End Cap

- Cut & Prep available upon request

- (1) 250-Truck_Float

- Fiber optic Cable (Length determined by the distance between the 808-P2 and 810-X Bar)

- ¼” Airline (Same length as fiber)

- (1) 1″ NPT Collar

- (1) Anchor Support

- 2-5 Conductor cable

- (1) 815-UHP/815-UHPH SpillStop

- (1) 815-JBC Junction Box

- (1) 688S MultiRack Controller

- (1) 688M Driver Module

Overfill Protection

Enhance the core system with overfill protection.

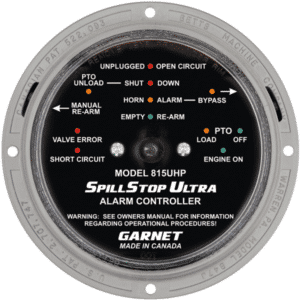

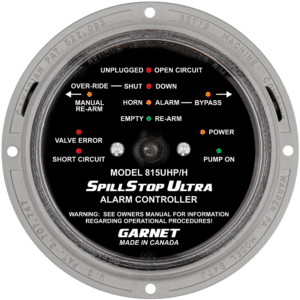

Alarm Controller with Hose Protection

Models 815-UHP & 815-UHP/H

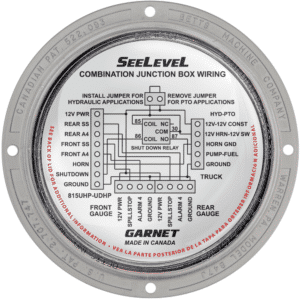

The SpillStop Ultra™ Alarm Controller works in conjunction with the SeeLeveL Special™ to provide an audible warning horn, high-level pump shut downs, and hose protection. This product increases safety and prevents spill-related costs. The SeeLeveL Junction Box™ can be added to simplify wiring.

- Provides automated control for hydraulic or PTO driven pumps

- Prevents spills and damage due to blown hoses

- Defaults to shut down condition if malfunctioning

- Weather resistant enclosure

- Operates on truck power

Under normal loading conditions, the SpillStop is wired an external warning horn and the loading pump. When the tank is being filled, the SpillStop will activate the warning horn and first level shut down at the alarm 2 set point pre-programmed in the 808P2. The alarm 2 set point is used to alert the operator that the tank is nearing full. Once Alarm 2 is activated, the horn alarm will sound AND the pump will shut off. At this point, the operator can press the bypass button on the SpillStop to silence the horn and regain the pump to clear the hose. However, if the operator continues to load to alarm 1 (High level shutdown)also pre-programmed in the 808P2, the pump will shut off and will not power up again until the tank level drops below the alarm 1 set point. Alarm 1 is used as a high level emergency shutdown and cannot be bypassed. As an added feature, the SpillStop can be wired to a pressure switch on the load line. If pressure on the load line spikes due to a valve being closed, the SpillStop will immediately shutdown the pump preventing hose blow-out.

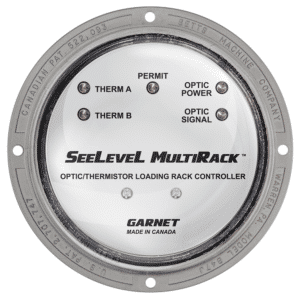

Optic/Thermistor Loading Rack Controller

Models 688-S / 688-D

The MultiRack™ Controller works in conjunction with the SeeLeveL Special™ to provide overfill control for optic and thermistor-style loading racks.

- Powered by the loading rack

- Provides automated control of external loading racks

- Single or dual compartments

- Weather resistant enclosure

- Intrinsically safe

- Diagnostic LED’s provide visual indication of rack plug condition and permit status

When an external loading rack is being used to load a tank with the SeeLeveL MultiRack Controller, the external loading rack will plug into the optic or thermistor sockets on the tank. At this point, the loading rack is now being controlled by the SeeLeveL system. The MultiRack Controller is driven off of a pre-programmed alarm point in the 808P2. When the tank level reaches this alarm, the MultiRack controller sends a signal to the external loading rack to stop the loading process and prevent overfill.

Additional Support Products

More components to enhance your system.

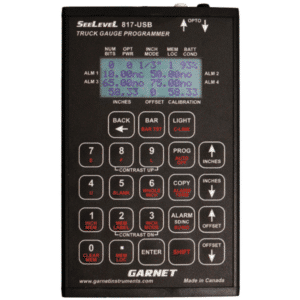

Truck Gauge Programmer

Model 817-USB

The SeeLeveL™ 817-USB Truck Gauge Programmer is used to program tank calibrations and alarms and to troubleshoot any SeeLeveL™ 800 series system. The USB interface allows tank calibration files to be created and stored on a PC or laptop.

- Works with all 800 series displays

- Used to test sender bar displays and fiber optic cable

- Operates on four alkaline AA batteries with no memory loss

- 32 memory locations for storing calibration charts

- USB port interfaces with your PC or laptop running our truck gauge programming software

- Simulates both display and sender bar to simplify system testing

- Convenient hand-held aluminum enclosure helps to avoid errors due to interference and static electricity

Remote Display & Data Portal

Model T-DP0301

The SeeLeveL Access™ gathers and ports data from the SeeLeveL Special™ or SeeLeveL Annihilator™ to a wide variety of ELD systems while displaying tank levels inside the truck.

- The SeeLeveL Access™ provides an easy-to-read LED display inside a compact, edge-mounted enclosure. This low-profile design is ideal for top-of-dash or overhead console mounting.

- The dimmer switch enables the operator to control brightness.

- A rugged aluminum enclosure is designed to withstand the vibration and shock encountered in mobile applications.

- Operates on 12 V truck power, drawing less than 150 mA.

- 4-20 mA output can be programmed to any full-scale value desired.

- The RS-232 digital interface provides secure level data as well as unit information.